The use of ores and the production of metals contributed greatly to the development of mankind. Most metals have a regular arrangement of atoms and nowadays it is possible to image the atoms, especially by advanced electron microscopy. Efforts of materials scientists during the last decades show that imperfections of the regular atomic structure of metals can be useful. This seems surprising but it is precisely this advantage of metallic materials we use in everyday applications.

An important question for material scientists is to deliberately introduce imperfections in the arrangement of atoms to improve the properties of metals. In this respect, imperfections that are called twins are of special interest. A twin occurring in the atomic arrangement is defined by two areas having an atomic structure in a mirror like position. These perfectly symmetric imperfections make it possible to yield a material with high hardness, good deformability and, additionally, good electrical properties. The phenomenon of twinning has been noticed for several metals, however, until now it seemed impossible to make aluminium with a high density of grown-in twins.

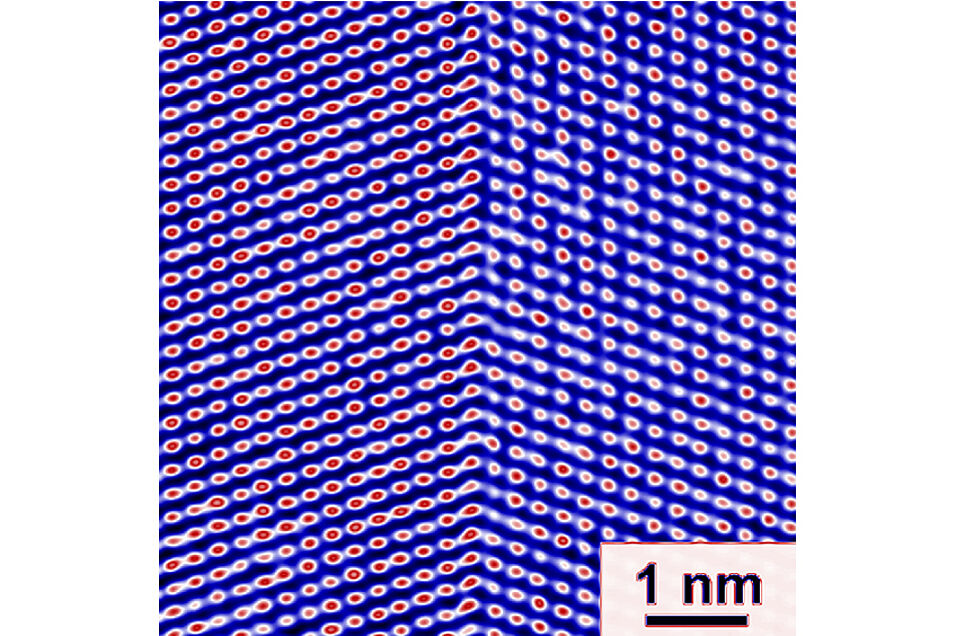

Therefore, Lidija Rafailović from the COMET Centre CEST in Wiener Neustadt and Christoph Gammer from the Austrian Academy of Sciences were very surprised when they observed a high density of growth twins in an aluminum layer deposited electrolytically. Christoph Gammer and co-authors from the University of Vienna, used advanced electron microscopy techniques to image this material with atomic resolution, and the high density of twins sparked excitement.

At this point, an important question arose how to understand this unexpected finding. The aluminum was deposited electrolytically in a complex process in which the sample builds up atom by atom from a liquid containing an aluminum salt. As a result of the joint effort of all authors headed by Peter Karnthaler from the University of Vienna a model was developed in cooperation with a team of computational materials scientists led by Igor Pašti from the University of Belgrade and KTH-Royal Institute of Technology in Stockholm. The model shows that individual hydrogen atoms present during the process of electrodeposition can trigger the formation of twins. The model is proposed to be of general applicability.

Although during electrodeposition the sample builds up atom by atom, coatings of large specimens can be made once the process is understood. Therefore, the results are not only of scientific interest, since they show that even marginal quantities of hydrogen can have an important impact on processes and reactions taking place at surfaces. The achieved twinned aluminum can have several potential applications replacing toxic cadmium coatings in the aerospace industry, or as a current collector in advanced batteries.

Scientific Publication:

“High density of genuine growth twins in electrodeposited aluminum”, Lidija D. Rafailović, Christoph Gammer, Christian Ebner, Christian Rentenberger, Aleksandar Z. Jovanović, Igor A. Pašti, Natalia V. Skorodumova and H. Peter Karnthaler; Science Advances 18 Oct 2019: Vol. 5, no. 10, DOI: 10.1126/sciadv.aax3894

Links:

Publication: https://advances.sciencemag.org/content/5/10/eaax3894

Research group “Physics of Nanostructured Materials”: https://physnano.univie.ac.at/